Cavitation Technologies, Inc.

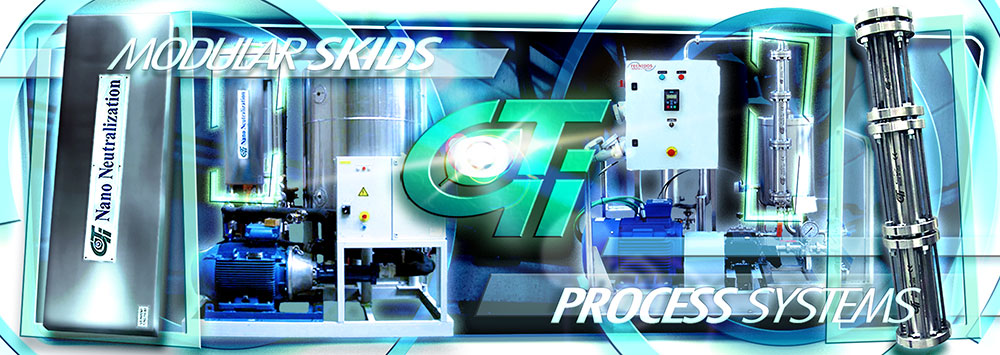

Cavitation Technologies, Inc. (CTi) is an innovative leader in processing liquids, fluidic mixtures, emulsions and suspended solids. The Company focuses on the practical implementation of in-house innovations and breakthroughs and sees its main mission as addressing the current and future needs of major industries. Founded in 2007, CTi designs and manufactures state-of-the-art, flow-through, robust, hydrodynamic cavitation-based devices and systems; the Company develops high-efficiency processing technologies for use in edible oil refining, algal oil extraction and renewable fuel production, biodiesel, alcoholic beverage enhancement, water treatment and expeditious petroleum upgrading. The Company is committed to operating in a responsible manner that ameliorates its environmental impact and pioneers technologies that save and protect natural resources.

The Company has commercialized its patent-pending CTi Nano Neutralization® process, offering the refiners of edible oils and fats significant yield improvements, substantial cost savings and environmental benefits. As an add-on to existing neutralization systems, the Company’s patented Nano Reactor® allows refiners to significantly reduce the processing costs, increase the yield and perfect the oil’s quality. The Desmet Ballestra Group, the leading global solutions provider for the edible oil and fats and biodiesel industries, has partnered with CTi to market this breakthrough technology worldwide to large-scale facilities.

NANO TECHNOLOGY REDUCES CO2 EMISSIONS

- Chemical Consumption approximately two-third less than conventional process

- Emission with up to one-third less GHG emission

- Better Sustainability with less chemical consumption

Today, CTi technology is being used on edible oil refineries worldwide to process over 350 million litres of edible oil per year.

Agents and Distributors Wanted

Existing/Pending Installations

Over the years CTi has built a fruitful partnership with oils and fats global leader Desmet Ballestra, and in 2012 CTi entered into a business agreement with GE Westfalia...

Core Technology Overview

CTi's core technology is based on hydrodynamic cavitation. Hydrodynamic cavitation comprises nucleation, fluid vaporization and growth, pulsation, if any, and the collapse of bubbles which occurs in a flowing fluid as a result of a decrease and subsequent increase in its static pressure…read more »

Corporate Overview

Cavitation Technologies, Inc. owns and markets patented and patent-pending devices and technologies that were developed to reduce processing costs, improve yield and mitigate the environmental impact of large-scale industrial liquid-processing applications… read more »

Edible Oil Refining

Eco-Friendly Benefits of Nano Neutralization®

- Yield increase 0.2% - 0.8%

- 90% less excess phosphoric acid

- 30-50% less caustic soda

- Low to zero silica consumption

- Lower soaps at primary separation

- CO2 decreased by 33.4%

- Patented technology and patent pending process

Water Treatment

Chemical Free Patented Process

One of the major challenges facing mankind today is to provide clean water to a vast majority of the population around the world. The treatment of wastewater prior to discharge and its reuse have become absolute necessities. CTi put a substantial R&D effort into designing a patented Cavitation & Electrocoagulation System for industrial water treatment...

Biodiesel Transesterification

Eco-Friendly Biodiesel

A major competitive advantage is our patented multistage cavitation reactors and patented process which we use for transesterfication in production of biodiesel.

- Reaction time reduction (instant).

- Increase in the reaction yield.

- Up to 30% less catalyst consumption

Biomass to Biofuels

BIOMASS AND BIOGAS

Renewable Energy Technology

More efficient and more cost effective process for producing biofuels, in particular bioalcohol, using hydrodynamic flow trough cavitation.

- Up to 35% increase in yield

- Reduces retention time

- Decreased energy consumption

- Patented technology and patent pending process

Petroleum Upgrading

The Company's proprietary technology of petroleum upgrading was shown to be capable of breaking down asphaltene agglomerates, improving both viscosity and API gravity for a prolonged period of time, reducing pumping and atomization costs, facilitating hydrocarbon cracking and increasing the refining yields… read more »

The Company's proprietary technology of petroleum upgrading was shown to be capable of breaking down asphaltene agglomerates, improving both viscosity and API gravity for a prolonged period of time, reducing pumping and atomization costs, facilitating hydrocarbon cracking and increasing the refining yields… read more »